News Release

UCSD Structural Engineers Honored for Contributions to New Bay Bridge

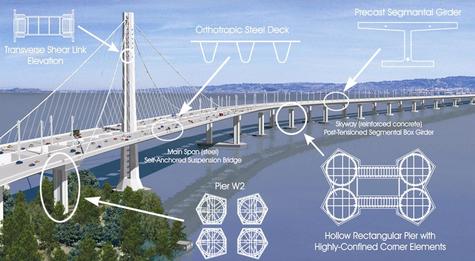

San Diego, CA, May 10, 2004 -- The American Society of Civil Engineering (ASCE) will honor two University of California, San Diego (UCSD) Jacobs School of Engineering faculty and a UCSD alumnus with the 2004 Leon S. Moisseiff Award for their co-authored paper titled, “Cyclic Testing of Built-Up Steel Shear Links for the New Bay Bridge,” that was published in the June 2003 issue of the ASCE Journal of Structural Engineering. The award will be presented at the 2004 Structures Congress & Exposition in Nashville, TN on May 25. The paper describes research to improve welding details on a new self-anchored suspension bridge (Figure 1), currently being built to replace the existing San Francisco-Oakland Bay Bridge East Span, which was damaged during the 1989 Loma Prieta earthquake. Jacobs School dean Frieder Seible and structural engineering professor Chia-Ming Uang are world-renowned researchers with expertise in large-scale, dynamic earthquake testing, analysis and design. The third member of the collaborative team, Cole McDaniel, obtained his Ph.D. from UCSD and is now an Assistant Professor at Washington State University. In 2001, at its Powell Structural Research Laboratories, the Jacobs School tested key structural elements in the main tower that supports the 1,850-ft long suspension bridge for the new San Francisco-Oakland Bay Bridge East Span. The design of the tower was based on original concepts developed at UCSD by Seible, who chairs the Caltrans Seismic Peer Review Panel for the bridge, and is member of the Metropolitan Transportation Commission (MTC) committee that selected the final design and designer. According to Seible: “This innovative, self-anchored suspension design includes a steel single-tower suspension span over the shipping channel near Yerba Buena Island and a concrete pier-supported ‘skyway’ from the suspension span to Oakland. The suspension span's single-tower and self-anchoring features represent important advances in bridge and seismic design." The new bridge is designed to withstand earthquakes in excess of those expected from the

After a large earthquake, the damaged links would be quickly replaced without significant delays or repairs to the overall structure. Although links have been used in building applications in recent years, links of such large size that require heavy welding have never been attempted for bridge applications. Seible was the principal investigator for all of the large and full-scale pivot tests in direct support of this seismic safety project for Caltrans. Under this Bay Bridge prooftest program, every type of structural element, designed to see inelastic action during the Safety Evaluation Earthquake, was tested to failure under simulated seismic loads under controlled laboratory conditions to evaluate performance, capacities and damage/failure modes. The full-scale shear link tests described in the paper showed that (1) the shear links can be used to protect the tower legs against inelastic action, (2) the overstrength of these sacrificial elements can be significantly higher than that specified in the seismic steel design code and, (3) proper detailing of stiffeners and welds can provide the required rotation capacity in the link zone. Specifically, large-scale testing of links conducted at UCSD revealed some unexpected and previously unobserved brittle failure. “The welding is rather complicated and can cause areas of high-stress concentration where pieces come together. This resulted in brittle fracture during tests, originating from the welding corners,” explains Uang. Jacobs School engineers used finite element analysis to demonstrate ways to avoid high-stress concentration points. The Journal of Structural Engineering paper describes measures proposed by the research team to avoid brittle failure. According to Uang, “The cracks initiated at a highly restrained region where several welds meet. Based on finite element analysis, we’ve recommended that vertical welds connecting the stiffeners to the link web be distanced from the highly restrained region by at least three times the web thickness. We also recommended that the ends of the welds be tapered to provide a smooth profile.” Their findings were later experimentally verified at the University of Nevada, Reno, and have been incorporated into the final design of the new bridge. The Jacobs School played a leading role in the entire proof test program for the new bridge, funded with $4.5 million from Caltrans. Proof testing consisted of seismic dynamic large-scale testing of the San Francisco-Oakland Bay Bridge East Span’s shear links, bridge deck, skyway piers, and W2 pier (Figure 3.). Construction on the project began in 2002 and is estimated to take five years to complete, at which point the existing bridge will be removed.

Moisseiff, for whom the award is named, was an esteemed bridge designer and consulting engineer on the San Francisco Golden Gate Bridge, which was begun in 1933. He theorized that a long span suspension bridge could cross the Gate, even though a suspension structure of its type has never been attempted. It is in this tradition that engineers at the Jacobs School have built a reputation for innovative bridge design. |

Media Contacts

Rex Graham

Jacobs School of Engineering

858-822-3075

rgraham@soe.ucsd.edu